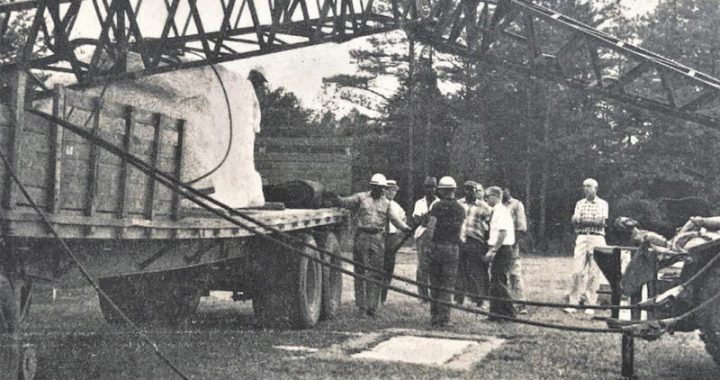

Fig. 1 Dropping Booms in the work area is an ole story!

A Study of Boom Luffing – PART 1

Published in the April issue of Wire Rope News & Sling Technology in the DENNY’S Crane Rigging and Notes column

by Dennis J. O’Rourke, CSP

Boom rope failures are historical. In 2020 we talked a lot about rope failures — message not received. Some people become philosophical and thoughtful upon aging, revisiting memorable events. I care because of my experience with accidents. We do not have a choice about aging. Caring is an option.

My first boom “falling” was at Cape Canaveral, FL in 1963 (22-B) — rope broke. Philosophy, a study of how we think through problems and develop theories using research to solve difficulties in a specific area. I selected why boom ropes fail. A major cause is inadequate or no maintenance.

Standards stress a “complete” annual inspection is necessary to solve the problem of taking worn ropes out of service. In this 1947 photo, we see, not too clearly, but visible in Fig. 1, boom failures are catastrophic. When a hoist rope breaks, the load drops straight to the ground (although load “splatter” is known to reach people 20′ away), fewer people are exposed to being hit. Dropping a boom, the entire work site is exposed. You’re either in the right spot or the wrong one, no ducking it!

Some maintenance people consider boom ropes of equal importance to any other rope, unmindful of their particular needs. All wire ropes wear-out quickly. In a crane’s life, ropes can be replaced as much as twenty to thirty times more often than the engine’s piston-rings or rod-bearing. Yet, these critical servants do not have “gauges” to let us know when they are low on oil, knocking sounds when wearing, or reservoirs religiously kept-full by mechanics. An engine blowing a rod has never killed — but a failed rope has. Are we missing something?

valleys before a new application.

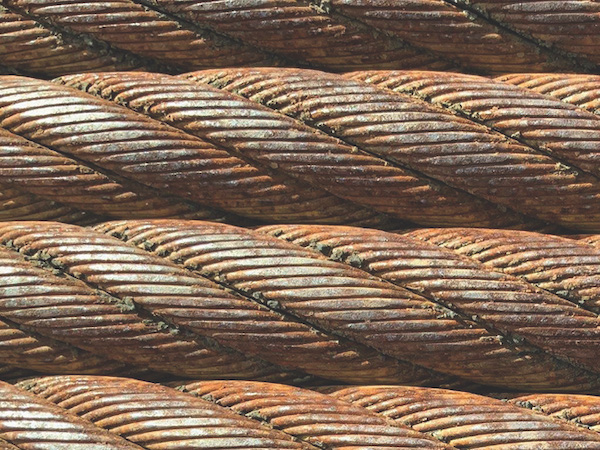

Severe wear locations (equalizer sheaves) must be viewed close-up each year. Requires taking the crane out-of-service for as long as needed. Some people do not correctly service the rope on their crane! Lubrication must penetrate the rope to the core allowing the wire to slide easily along each other, reducing friction and wire breaks at the “strand to strand” contact area. Fig. 2 shows valleys clogged with dried-hard lubricant — how can a light spray of oil penetrate to the core — it cannot and best applied when bent over sheaves. This dry lubricant must be removed before applying a penetration oil. How often? As often as it takes to prevent reoccurrence. When was the last time you saw a crew removing dry lubricant from a rope? There are rope cleaning devices available. Check ads in this magazine.

A heavier lubricant for external corrosion is needed. Some say their lubricant can protect for a year; time intervals depend on the environment. The extra time spent on these critical ropes is worth the effort. To protect the rope, extending its life, use a heavier lubricant that sticks to the rope. Here is the dilemma. To lubricate the rope’s wires to the core requires a light viscosity lubricant. Learn how to penetrate the inside of the rope and also protect the outside of a rope.

wires start breaking.

If not failing at the equalizer sheave (some reeving systems do not have equalizers) or from rusty ropes. Another causation is broken wires due to fatigue. Not all the rope’s length is subject to outer wire wear; find their location and mark. The wirers are scrubbed on the drum then bent around sheaves under tremendous pressure, ouch! Fig. 3. When the wires wear thin and flat, they break when bent; that simple, 1/3 diameter wearing is allowed. Proper outer lubrication reduces wear.

A “test” — do you know the rope construction shown in Figs. 2 & 3? An inspector should, yet I have met some that did not — but were inspecting rope. OSHA (1926.1412) says a competent person — demonstrating the skill — shall make an annual rope inspection. It matters that inspectors know what they are looking at — to be called an “informed judgment.”

If you have a good rope lubrication crew, you can have a good inspection crew. With proper training, eliminating these enduring catastrophe boom rope failures is possible!

PART 2 in the June issue of Wire Rope News & Sling Technology

ABOUT THE AUTHOR

DENNIS J. O’ROURKE, CSP, is the Director of National Crane Services, Inc. He has over sixty years’ experience in the industrial, maritime, and construction fields working with heavy equipment and material handling devices. As a safety engineer, Mr. O’Rourke has developed and/or presented hundreds of safety-training programs for all representative elements of government and industry. (dennis@natlcrane.com)