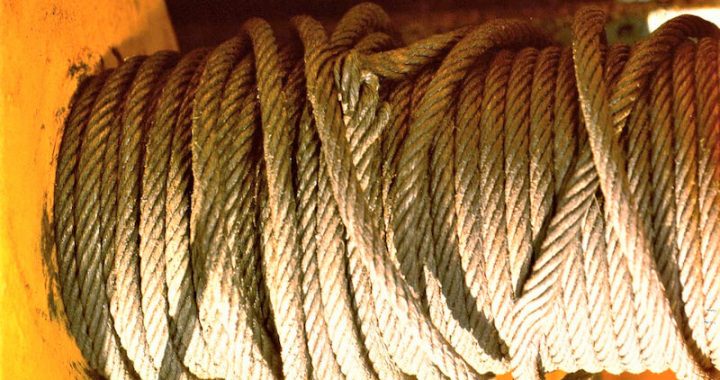

Fig. 1. Spooling off top layers reviled this mess!

Hoist Drum Spooling: Good or Bad!

Published in the October 2020 Issue of Wire Rope News & Sling Technology, Denny’s Crane and Rigging Notes

by Dennis J. O’Rourke, CSP

In the distant past, the excess lead line needed to raise a load was just coiled up on the deck or ground. Letting it just layout/coiling-up was acceptable because the “pulling force” was a horse or by hand. When lead line pulling power was converted to a mechanical winch drum, and then progressed to higher torque and many layers of line, a problem came to light.

To cause the ugliness in this first picture is not all that hard to accomplish, and ever so often occurs. Now, we discuss how the equipment design helps or hinders drum spooling.

Accessories like level-wind, slack-rope devices, and spring-tensioned rollers helped better spooling and were introduced to stop rope damage. However, they are equipped on just a fraction of the winches and are unsuitable for many applications.

Multi-layering on drums increases pressure, and “diving” occurs, which means that the lead-line tension pulls the rope down through the top layers! A dangerous condition — the only remedy is to lower the load to the ground and hope that all the snapping and popping doesn’t break anything. If the Crane’s capacity allows it and there is space — boom down to set the load, thus, not rotating the hoist, best. Fixing the problem may take days!

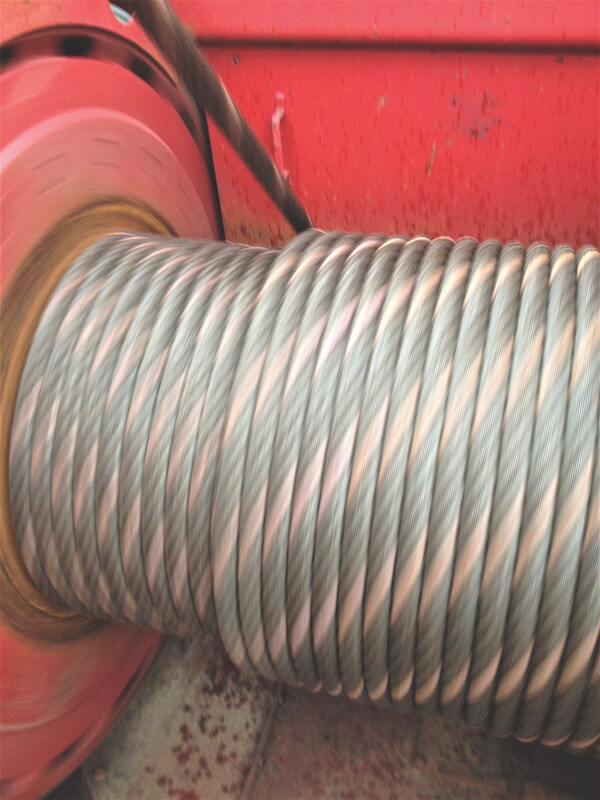

In a perfect world, all spooling would look like the drum in photo two. Port cranes have lots of room for the ideal hoist drum location, allowing a generous PD/RD “pitch” diameter reducing the rope’s internal bending stress.

The grooved lagging provides uniform rope wraps and support; the diameter of the drum allows a single layer winding, best! The weight of the rope and the distance between the drum and the first deflecting sheave provides needed fleeting angles for spooling. The winch also is equipped with a slack-rope device that stops the winch rotation (if occurring) that could damage the rope. Slack-rope is what caused the condition in Fig. 1 (above)

The design of the drum effects spooling. The first layer of wraps determines the evenness of the next. The lower layers must be compact, providing the support of those above. An advancement in ensuring tight rope wraps (wrap = one complete rotation) was grooved vs. a smooth drum face. Some of these grooves can be replaced when worn-out, then the grooves are referred to as “lagging.”

Fig. 2. Near ideal hoist design

Fig. 3. Rope fleeting angle provides proper spooling.

“Fleeting” is a factor of drum spooling, Fig. 3. Fleeting is the “motion” of the rope as it moves from flanges to flange. A fleeting-angle of about 1½ degree from the center to the flange is required. The angle guides the rope from one side to the other, so the rope is inclined to go back and forth. In photo three, you see a pattern of the rope’s “marker strand” (pink) of the wraps on the drum — a right-hand turn over the left-hand turn of the lower layer. The two different fleeting directions cause the wire wear on drums. And why proper rope lubrication (reducing metal to metal scrubbing) is necessary.

Controlling the fleeting angles on a lot of Cranes is by using a sheave able to slide along a lubricated shaft the length of the drum’s width. Their function is to maintain the correct fleeting angle for spooling. All fleeting sheaves are equipped with a guard. It’s critical that the rope remains in the sheave-groove when operating and doesn’t jump off and get crushed or cut being pulled through the machine.

Depending on Crane design, reinstalling and adjusting the guard can be easy, or located 100 feet in the air. Checking the position of guards may sound like an obvious task, but, found to be often overlooked; a grave mistake. Ropes jumping off sheaves have caused fatal accidents.

It all comes down to maintenance training. You must know your Crane’s “wants and needs” to be safe.

DENNIS J. O’ROURKE, CSP, is the Director of National Crane Services, Inc. He has over sixty years’ experience in the industrial, maritime, and construction fields working with heavy equipment and material handling devices. As a safety engineer, Mr. O’Rourke has developed and/or presented hundreds of safety-training programs for all representative elements of government and industry. (dennis@natlcrane.com)